Achieving safe wire connections is a critical skill.

Introduction

Making safe, dependable wire connections is critical to any wiring job. Loose wires cause arcing, tripped breakers and electrical fires, so whether you're a DIY homeowner or an experienced electrician like me, you must be able to confidently and repeatedly make safe wire connections every single time you pick up your tools.

When I was in the field, and something wasn't working, the very first things I'd check were the splices and terminal connections. More often than not, I'd hit the jackpot. (Seriously, I'd take the "over" even at 90%). Below, I'll walk you through multiple ways to make basic wire connections in your home. But first, the rules:

- Turn off the power when working with electricity.

- Make sure the power's off using a non-contact voltage tester or multimeter.

One final tip: Get into the habit of making connections in this order: equipment grounding conductor (bare/green wire or screw), neutral (white wire or silver screw), then hot (black/red wire or brass screw). Disconnect in the opposite order. This reduces your chance of shock if the power is somehow still on. And if you're not sure what wire goes where, call a licensed electrician.

Tools Required

- 4-in-1 screwdriver

- Lineman's pliers

- Wire strippers

Materials Required

- Wire connectors (twist-on or push-in or lever nuts - aka Wagos)

Project step-by-step (7)

Choose the Right Connection Type

- Determine whether you will be using twist-on wire nuts, push-ins, lever nuts or screw terminals.

- Twist-on wire nuts are a traditional, inexpensive choice that work for most splicing applications.

- Lever nuts, aka Wagos, work well with too-short wires, full electrical boxes, or multiple wires that are hard to combine under a single wire nut.

- Push-in connectors are similar to lever nuts but do not have an easy-release lever.

- Screw terminals are used when connecting a circuit wire or pigtail (a short section of wire) directly to a switch, receptacle or other device.

- Read the package or instructions to determine the number of wires that the connector can safely handle.

- Every listed wire connector has a minimum and maximum size and number of wires for which it is rated.

- Push-in connectors and lever nuts have ports to receive the wires. You do not have to use all of them.

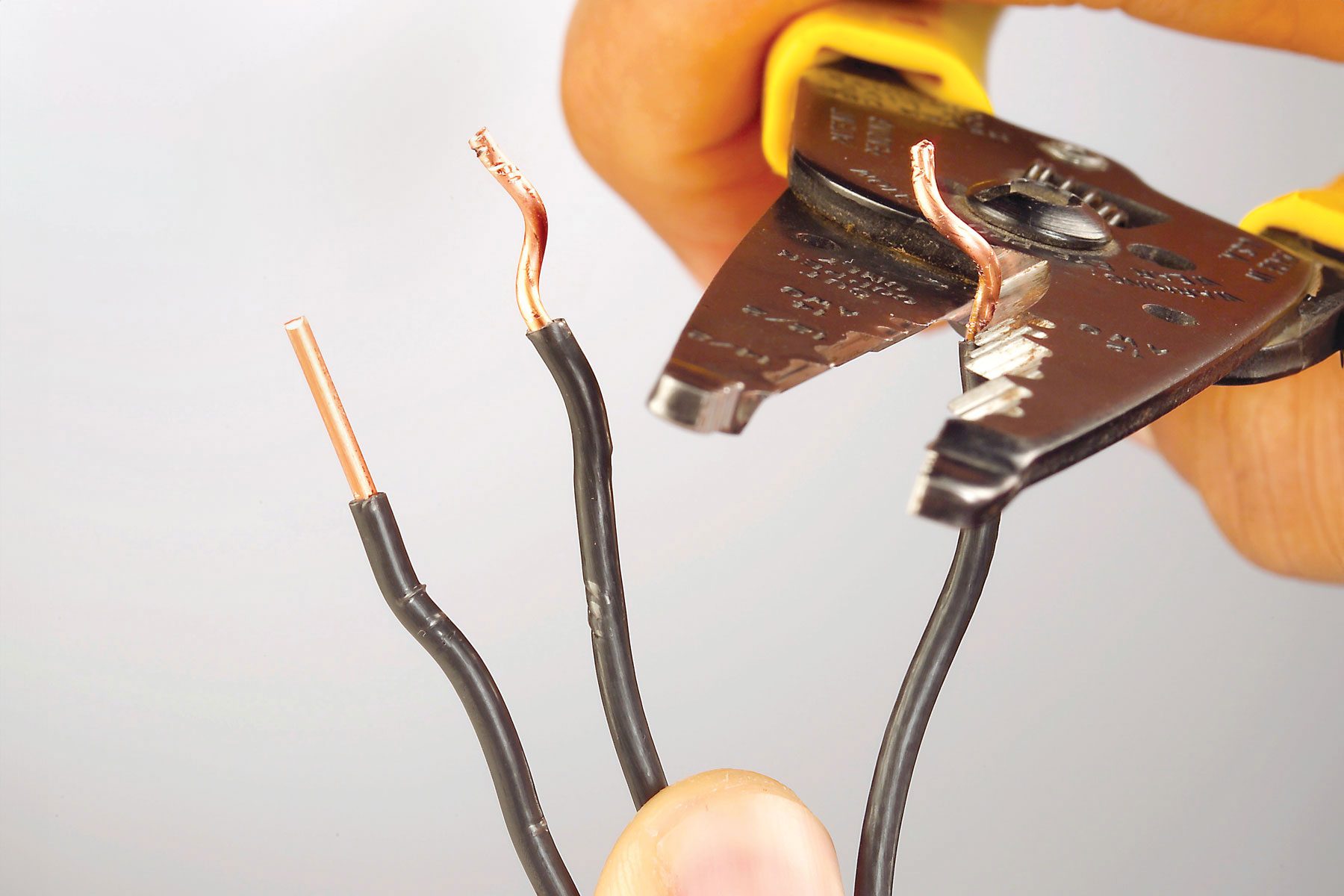

Prep the Wires (Connectors)

- Snip off the end of the wire. Old, twisted or nicked wires are harder to strip and less efficient conductors.

- Find the labeled cutting groove on the strippers that matches your wire size and type (solid or stranded).

- Strip off about 1/2 inch to 5/8 inch of the wire’s insulation with your strippers.

- How much you remove depends on the connector type. Check the package for details.

- Avoid nicking or gouging the wire when stripping the insulation.

Prep the Wires (Screw Terminals)

For solid wires:

- Snip off the end of the wire to give yourself a fresh section of conductor to terminate.

- Strip about 3/4 inch of insulation from the end of the wire.

- Make a hook at the end of the conductor by bending it with your strippers or pliers.

For stranded wires:

- Snip off the end of the wire to make it easier to pull off the insulation.

- Place your strippers about 1-1/2 inches from the end of the wire.

- Squeeze the strippers and begin removing the insulation, stopping when you have about 3/4 inch of exposed conductor.

- Leave the insulation attached.

Make the Connection (Wire Nuts)

- Gather the stripped conductors that you will be splicing into a bundle.

- If the wires are all the same type, keep the ends even with each other.

- For a mixture of stranded and solid wires, position the ends of the stranded wires about 1/8 inch beyond the solid wires.

- Place the wire nut over the ends and hold firmly while you twist.

- Continue twisting as you feel for the internal spring to engage with the wires.

- If the wires fall out, or you keep twisting and nothing tightens, readjust and try again.

- Stop when the wires are tightly bound and secure. You want the connection tight, with no movement.

Make the Connection (Push-Ins and Lever Nuts)

- Visually confirm that your stripped wires are the right length.

- Exposed conductors should be completely contained inside the connector when finished.

- Open the levers, if present.

- Push one wire at a time into the connector as far as it will go, using one port (hole) per wire.

- Snap down the levers, if applicable. If using push-ins, the connector automatically engages the wire.

Make the Connection (Screw Terminals)

For solid wires:

- Wrap the hook you made earlier clockwise around the terminal screw. Squeeze the hook closed around the screw.

- Tighten with a screwdriver.

For stranded wires:

- Tightly twist the strands counterclockwise, then wrap the twisted strands clockwise around the terminal screw.

- Make sure all strands are contained under the screw. Leave the ring of insulation attached to help. (Trim if desired.)

- Tighten with a screwdriver.

For clamp-style terminals:

- No hooks or twisting are needed. Trim solid or stranded wire to length and insert into clamp-style terminals.

- Tighten with a screwdriver.

Check the Connections

- Tug on all connections to make sure they are secure.

- Close up electrical boxes.

- Turn on the power and check your work.