Save money by building this handy table. It's easy. We'll walk you through the steps.

A day

Beginner

$30 to $40

Introduction

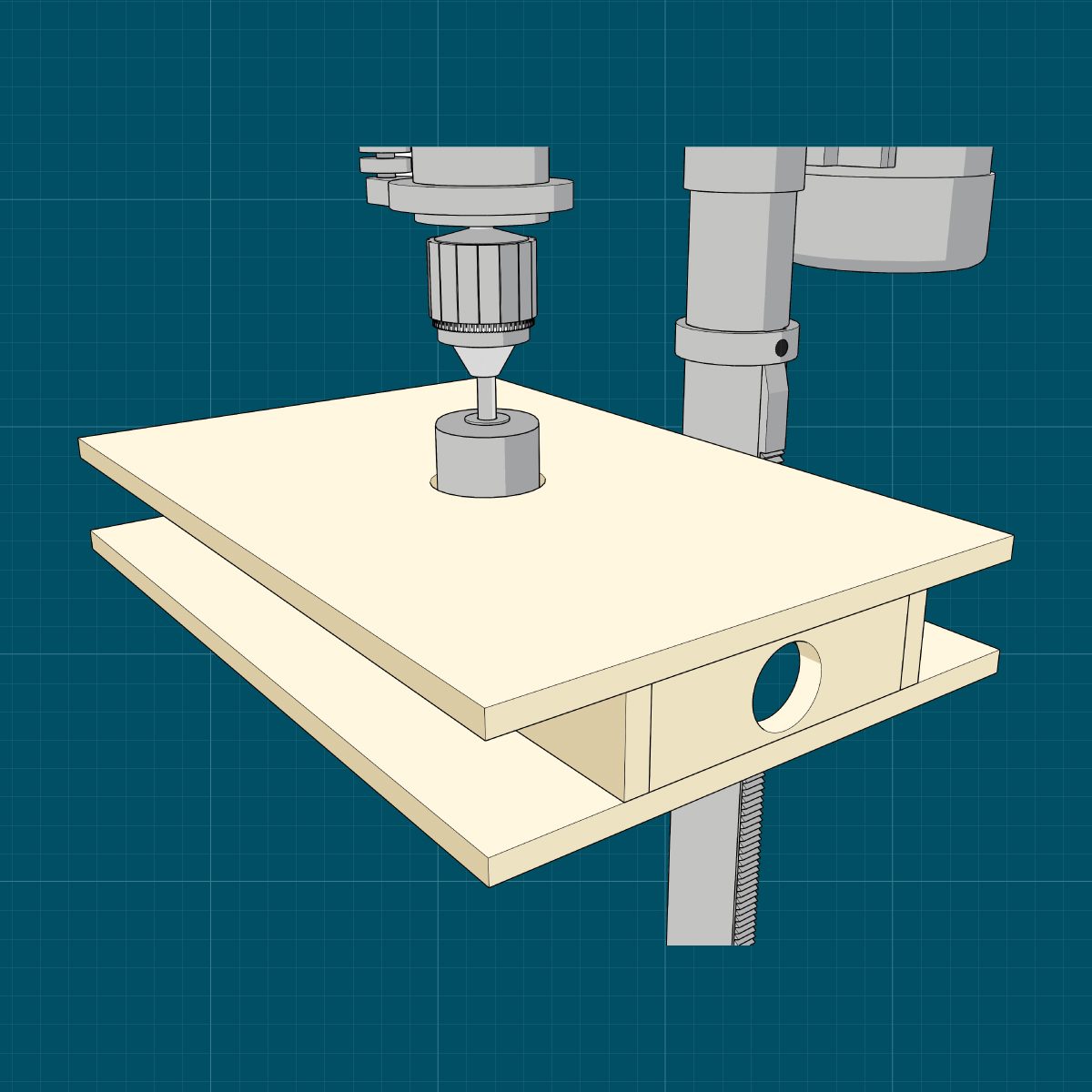

Oscillating spindle sanders can be expensive. Plus, who needs to find room for another tool in their shop?

This DIY drum sanding table can be made in an afternoon. And because it mounts on a drill press, it's automatically variable speed. Attach a vacuum hose and you won't want to do your edge sanding any other way.

Cutting List

| KEY | QTY. | DESCRIPTION | DIMENSIONS |

| A | 2 | Top and Bottom | 12″ x 18″ x 1/2″ |

| B | 2 | Side Plate | 1-7/8″ x 18″ x 1/2″ |

| C | 2 | Cross Beam | 1-7/8″ x 6″ x 1/2″ |

Tools Required

- 3/8" drill bit

- Drill driver

- Drill press

- Forstner bit set (or hole saw kit)

- Table saw

Materials Required

- (1) 24" x 48" x 1/2" MDF panel

- (4) 2-1/2" x 3/8-16 carriage bolts

- (4) 3/8-16 wingnuts (or threaded knobs)

- (8) 1" fender washers

- #8 1" wood screws (box)

- Wood glue (optional)

Project step-by-step (8)

Step 1

Cut the parts

- Cut the parts on the table saw. Because we’re using medium density fiberboard (MDF), there’s no concern for grain direction.

Step 2

Prepare the bottom

- Place the bottom on your drill press table. From the underside, outline the mounting slots with a pencil. This will tell you where to drill the holes.

- Drill 3/8-inch holes in a square pattern.

Step 3

Insert carriage bolts

- Pound the 3/8-inch carriage bolts into the bottom. The square seat of the carriage bolts should be enough to keep them from spinning in place.

- Pro tip: If you’re concerned the bolts will spin in their holes, apply a dab of epoxy or cyanoacrylate glue (aka CA or super glue) to the threads near the head.

Step 4

Prepare the top

- Mark the center of the top by drawing two diagonal lines from corner to corner.

- Drill a 2-1/4-inch hole with a Forstner or hole saw bit. If you have sanding drums larger than 2-1/4-in., drill your hole to match.

Step 5

Cut the vacuum port

- Drill a 1-5/8-in. hole in one of the sides to accept your shop vacuum hose.

- Pro tip: Vacuum hoses vary in diameter. If you don’t have an exact match, choose a hole size slightly larger and make up the difference with duct tape. This will actually help keep the hose in place.

Step 6

Make the riser box

- Screw the front and back riser blocks to the sides using 1-in. wood screws and a little wood glue.

Step 7

Attach the top

- Center the top on the riser and drill counter-sunk pilot holes.

- Attach it using 1-in. screws.

Step 8

Complete the sanding table

- Repeat the same process for the bottom, attaching it to the riser block with 1-in. screws.

- Drop the completed table on to your drill press table and tighten the wing nuts on the carriage bolts. Use fender washers, if needed.

- Insert your sanding drill in the drill chuck, lock the quill in the down position and plug your vacuum hose into the port. You now have a variable-speed drum sanding table in your shop.