Choose Double-Lock Casters

Swiveling casters often come with built-in locks. No surprise there, but did you know that there are two different kinds of locks?

A standard lock prevents the wheel from turning but doesn’t stop the caster from rotating around its plate or stem. A cart or machine with these casters won’t roll away when locked, but it will jiggle when pushed. If you put them on a cabinet supporting a tool, a workbench or anything else that has to solidly lock down, you’ll be sorely disappointed. A double lock totally freezes the caster. The wheel won’t turn and the caster won’t rotate.

Choose Large Casters

Small casters may be inexpensive, but they take a heavy toll on your back—and on your patience.

Equipped with too-small wheels, a cart or machine is hard to push: You may have to lunge at it just to get going. Once you’re up to speed, every little crack or crevice in your floor will stop you dead in your tracks. If you bump up against a screw or nail that rolled off your bench or one of the small chunks of wood that undoubtedly litter your shop’s floor, you have to remove the offender or change direction. Talk about annoying!

For moving heavy loads or maneuvering over an uneven floor, go big. The problems mentioned above won’t go away, but they will be minimized. Use casters that are at least 2 1/2 in. in diameter. Casters up to 4 in. in diameter are best for really heavy stuff. The larger the caster, the less muscle power you’ll need to get rolling and keep rolling.

How to Arrange Casters

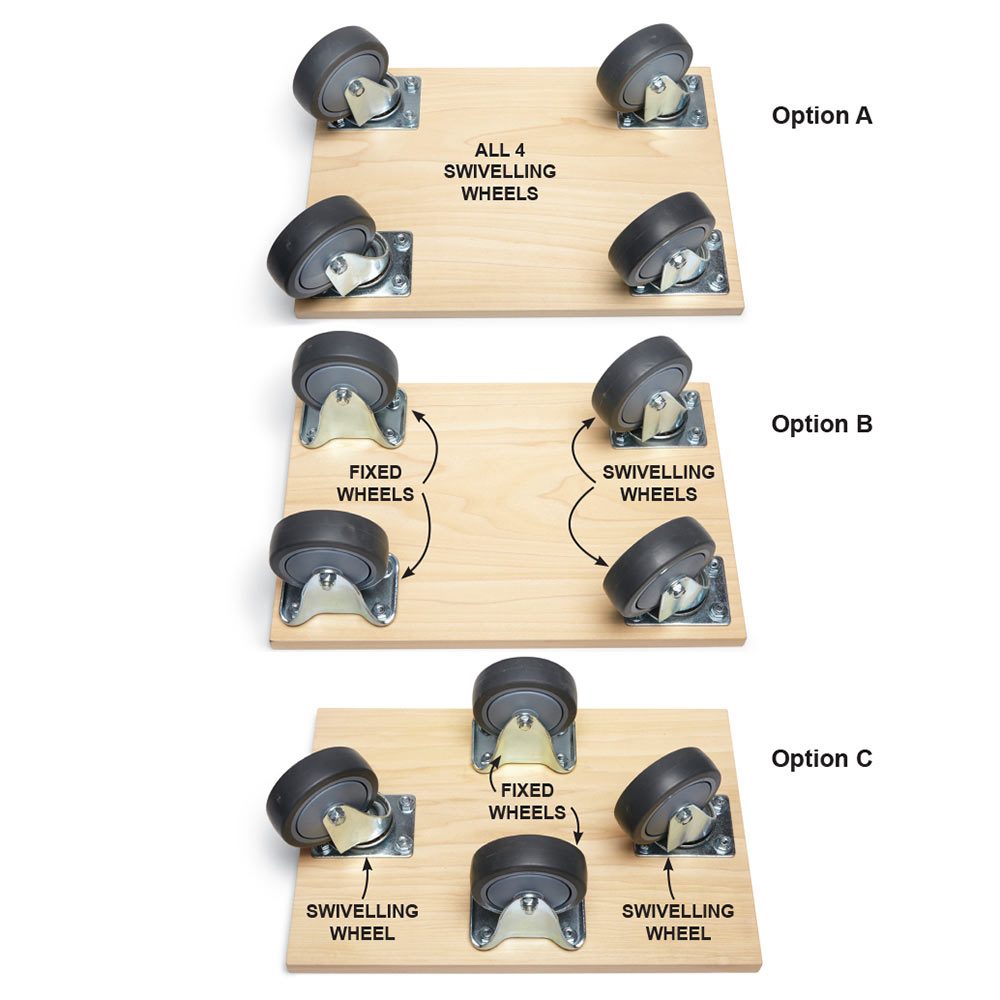

When most people put a cart or cabinet on wheels, they buy four swiveling casters and put one at each corner (Option A). Two other configurations are also worth considering.

You could substitute two fixed casters for two that swivel (Option B). Alternatively, you could move these casters to the center of each side of your unit (Option C).

What’s with all these options? Well, the choice comes down to whether you want your unit to be easy to maneuver into a tight space or easy to push in a straight line—or somewhere in between.

Option A, with swiveling wheels at all four corners, is best for parking your unit in a tight spot. If your shop is small and crowded, this is the way to go.

Option B, with fixed wheels at one end and swiveling at the other, is arranged just like your car or a grocery cart. A unit with this configuration tracks nicely and is easy to steer; it’s best for shops with plenty of room.

Option C, with wheels placed on centers rather than in the corners, is a good compromise between A and B. Carts used in railway stations and factories years ago were usually built this way. They could spin on a dime, but they also tracked well. This configuration does have a couple of disadvantages, however. First, the corners are tippy, so you must evenly distribute a load. Second, this arrangement doesn’t work on a cart with four legs. It’s really meant for a cart with a platform base.